2025/10/22

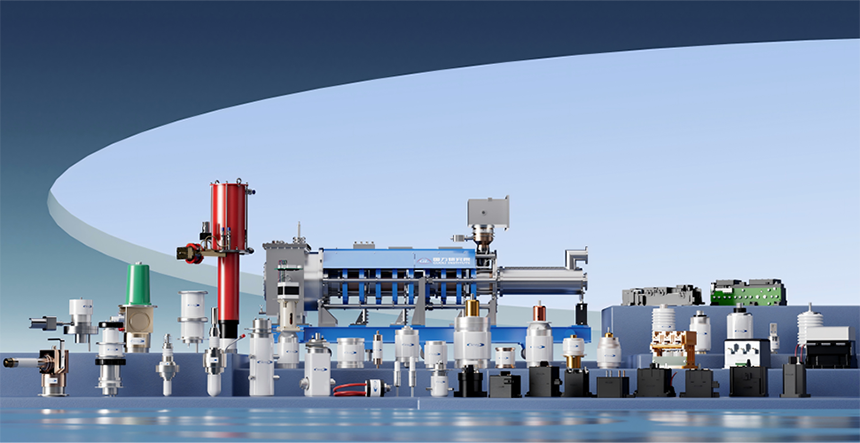

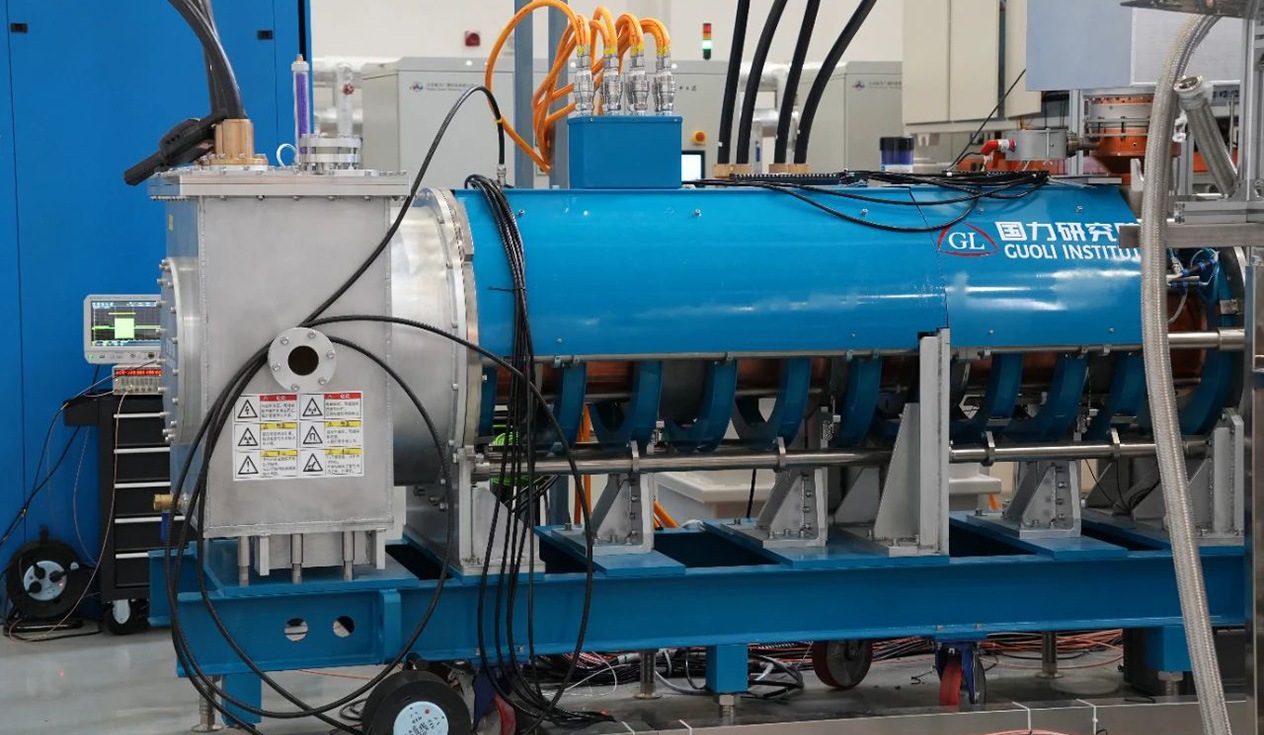

In the power equipment system, the vacuum Interrupter, as the core component of the vacuum switch, plays an important role in connecting, carrying, and breaking current. This article will introduce the basic principles, structural characteristics, and application advantages of vacuum switch tubes from a technical perspective.

01. Technical Overview

Vacuum interrupter is an electronic device that uses high vacuum insulation medium and special contact structure to achieve circuit closing and opening functions

When the vacuum switch needs to disconnect the circuit, the contacts separate in the vacuum and generate an arc. The arc quickly extinguishes due to its own metal vapor when the current crosses zero, thereby achieving circuit interruption. Its technical principle is based on three characteristics of vacuum environment:

High insulation strength: Gas molecules are rare in a vacuum environment, making ionization breakdown difficult. The insulation ability is better than that of air and oil media.

Strong arc extinguishing ability: The metal vapor generated by the arc rapidly diffuses and recombines in vacuum, and can quickly restore insulation when the current crosses zero.

Environmental adaptability: The internal vacuum medium does not produce harmful gases and meets environmental protection requirements.

02. Structural features

The vacuum interrupter is mainly composed of the following components:

Insulation shell: Made of high-strength aluminosilicate glass or high-purity alumina ceramic, ensuring high vacuum sealing and structural strength.

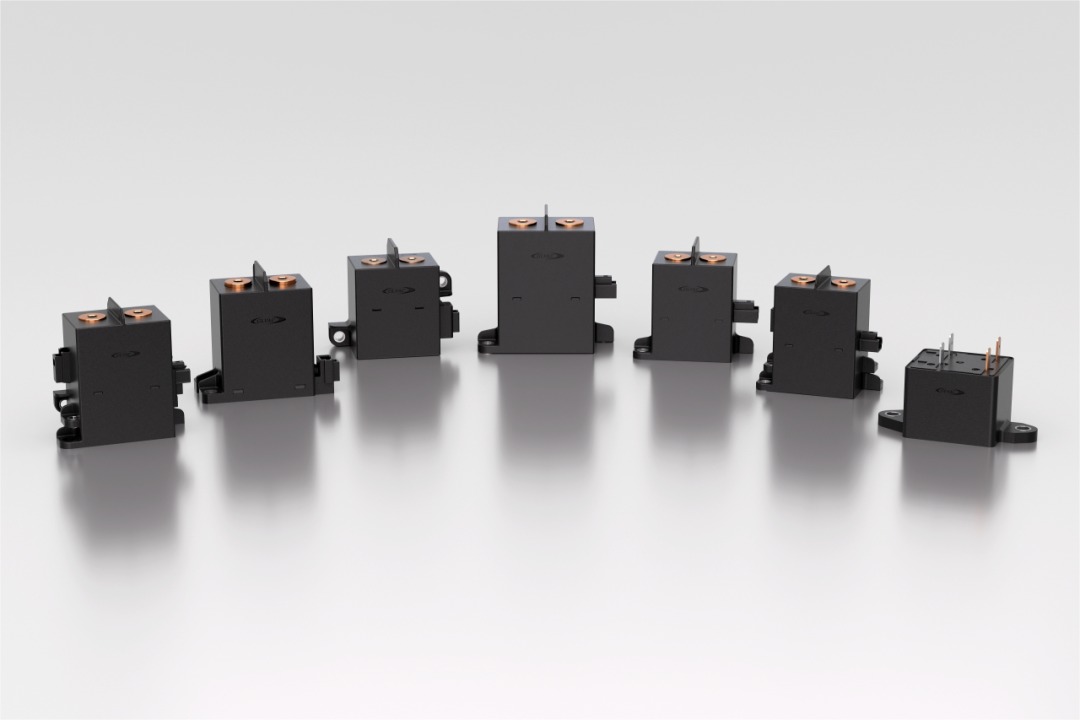

Contact system: Made of materials such as copper chromium (CuCr), it has the characteristics of arc erosion resistance, high conductivity, and low current interception level. The spiral groove magnetic control structure can generate a transverse magnetic field when breaking current, driving the arc to rotate and improving the breaking ability and contact life.

Shielding system: Multiple metal shielding covers can prevent arc products from contaminating the insulation shell, evenly distribute the electric field, and absorb arc energy.

Bellows: Made of stainless steel material, it achieves linear motion of the moving contact in a vacuum environment through elastic expansion and contraction, while maintaining vacuum sealing.

03. Technical advantages

In the field of 1.14kV-40.5kV medium voltage distribution, vacuum interrupter has become the mainstream technical solution, and its main advantages include:

Reliable operation: no explosion or fuel injection risks, strong ability to disconnect fault currents.

Easy maintenance: Sealed structure design, no internal maintenance required, reducing lifecycle costs.

Long service life: Long electrical and mechanical life, with tens of thousands to millions of operations.

Environmental characteristics: free of SF6 greenhouse gas, suitable for the green development needs of the power grid.

Compact structure: Small in size, convenient for device miniaturization and intelligent design.

Based on these technological characteristics, vacuum interrupters have been widely used in fields such as power grid renovation, new energy power stations, industrial electricity, and building power distribution.

04. Quality Control

The production and manufacturing of vacuum interrupters involve multiple key process steps: selection and processing of contact materials, ceramic metallization treatment, high-temperature vacuum sealing, etc. Each product must undergo strict tests such as power frequency withstand voltage, impulse withstand voltage, X-ray testing, and vacuum measurement to ensure product consistency and reliability.

Vacuum interrupter, as an important development direction of power switch technology, reflects the application value of vacuum breaking technology in modern distribution systems. This product plays an important role in improving the reliability of power grid operation and adapting to the needs of energy transformation.

Latest News

Get Professional Solutions

We are looking forward to engaging with you to explore more solutions for electric vacuum devices.