2025/12/19

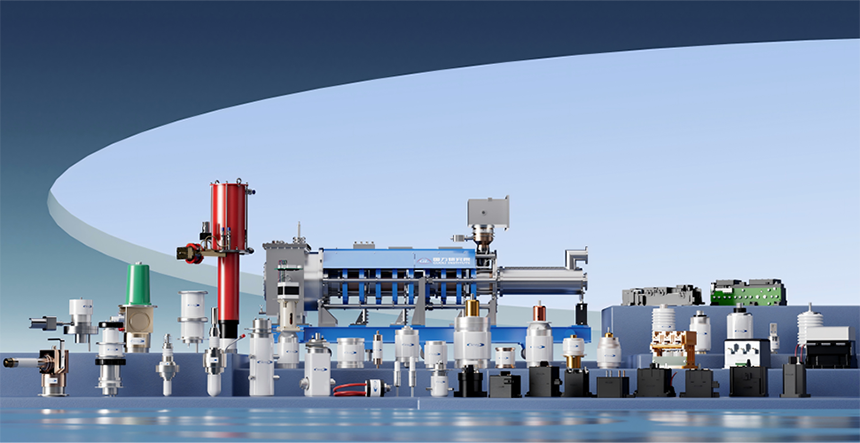

In the evolution of microwave technology, the magnetron has played a pivotal role. Among its various types, the continuous wave (CW) magnetron stands out as a crucial component due to its ability to deliver stable, continuous microwave energy over extended periods. This unique characteristic makes it indispensable across numerous fields—including semiconductors, industrial manufacturing, healthcare, and food processing. From microwave thawing and drying of food, industrial cracking and sterilization, synthetic diamond production, to microwave therapy devices in medical applications—the CW magnetron is ubiquitous.

01.What Is a Continuous Wave Magnetron?

In simple terms, a continuous wave magnetron is an electron vacuum device capable of generating high-power microwave energy continuously and stably over long durations. The term “continuous wave” distinguishes it from “pulsed wave” operation. By applying a steady DC high voltage, electrons inside the device move continuously under the influence of perpendicular electric and magnetic fields, thereby generating microwaves at a constant frequency.

02.Technical Advantages

Continuous Power Output

This is its defining feature, enabling stable microwave power delivery ranging from several hundred watts to tens of kilowatts.

High Efficiency

It exhibits excellent conversion efficiency—typically between 50% and 80%—transforming DC electrical energy into microwave energy with minimal loss, thus reducing operational costs.

Relatively Fixed Frequency

The operating frequency is primarily determined by the physical dimensions of the anode block’s resonant cavities. Consequently, once manufactured, its frequency tuning range is very narrow. Common industrial frequencies are 915 MHz and 2450 MHz, suited for diverse microwave applications.

03.Application Scenarios

Food Thawing and Sterilization

In industrial food processing, microwave thawing and drying represent the most common uses of CW magnetrons. The continuous microwave energy penetrates the surface of frozen food, causing water molecules within to vibrate rapidly. Heat generated through molecular friction enables rapid, uniform heating. The stable output of CW magnetrons ensures efficient and even food processing, making them ideal for large-scale food production and central kitchen operations.

Industrial Cracking, Rubber Desulfurization, Wastewater Treatment, and Metal Smelting

In industrial settings, CW magnetrons are widely employed in high-temperature processing, sterilization, sintering, and cracking. For instance, in the ceramics industry, microwave sintering equipment powered by CW magnetrons enables uniform internal heating of ceramic green bodies, significantly shortening sintering time while enhancing product density and performance. Additionally, CW magnetrons are used in rubber vulcanization, chemical feedstock heating, and metal smelting—driving industrial processes toward greater efficiency and sustainability.

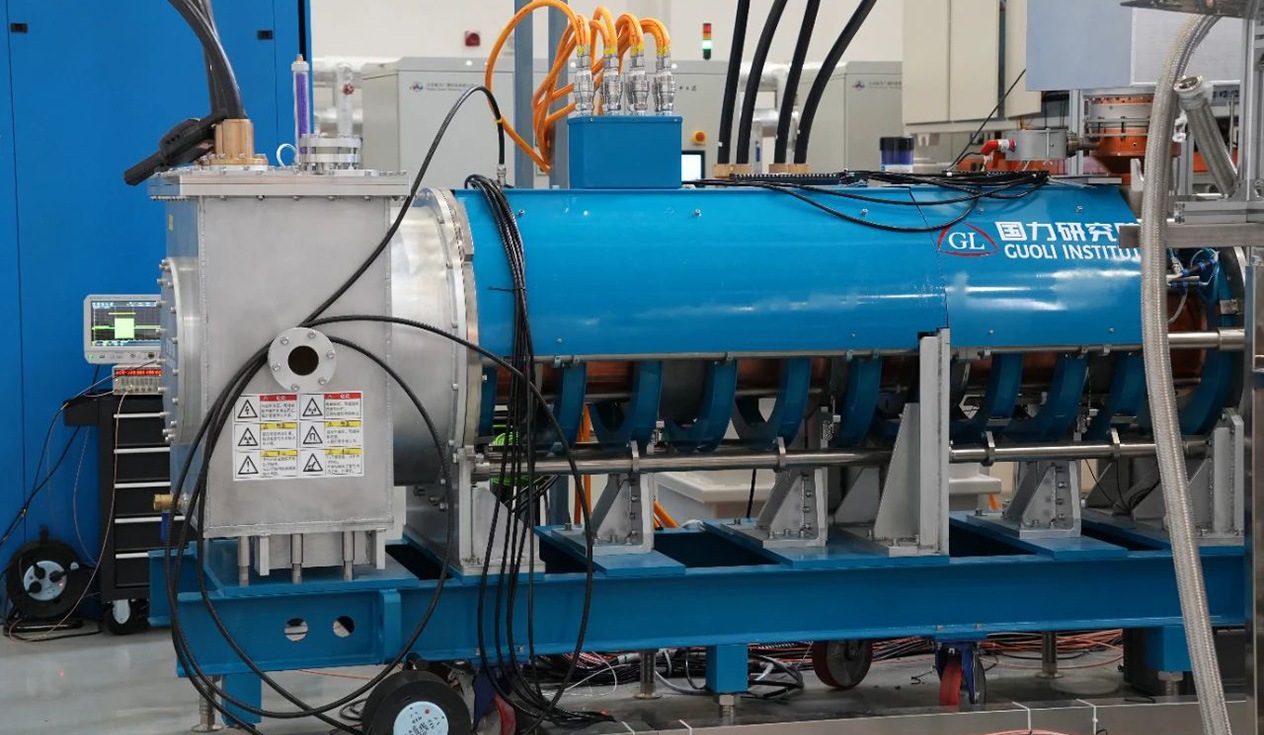

Plasma Applications

CW magnetrons also find use in plasma generation. In materials science research, microwave plasma generated by CW magnetrons facilitates surface modification and thin-film deposition experiments.

Microwave Medical Applications

In healthcare, the CW magnetron serves as the core component of microwave therapy devices, primarily used in microwave physiotherapy.

As a mature microwave energy source, the continuous wave magnetron—thanks to its distinctive capability for continuous output—provides robust technical support across food processing, industrial manufacturing, scientific research, and beyond. Its development mirrors the journey of microwave technology from laboratory experimentation to real-world implementation. With ongoing advances in materials science, vacuum technology, and electromagnetic field theory, CW magnetrons are poised to achieve breakthroughs in higher efficiency, smaller size, and longer operational life—thereby opening broader horizons for innovative microwave applications.

Latest News

Get Professional Solutions

We are looking forward to engaging with you to explore more solutions for electric vacuum devices.