Company News

2025/10/14

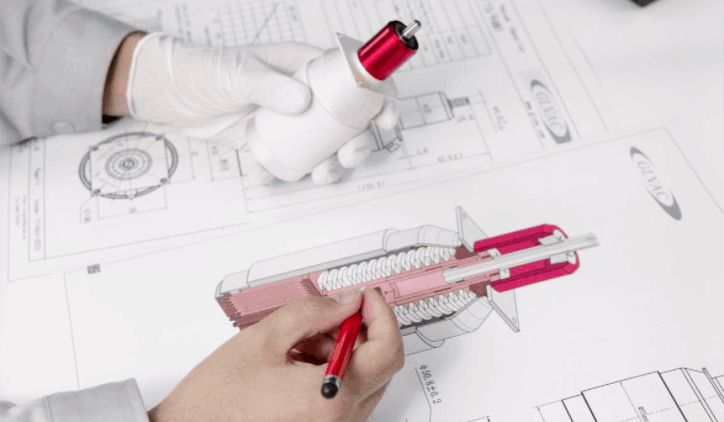

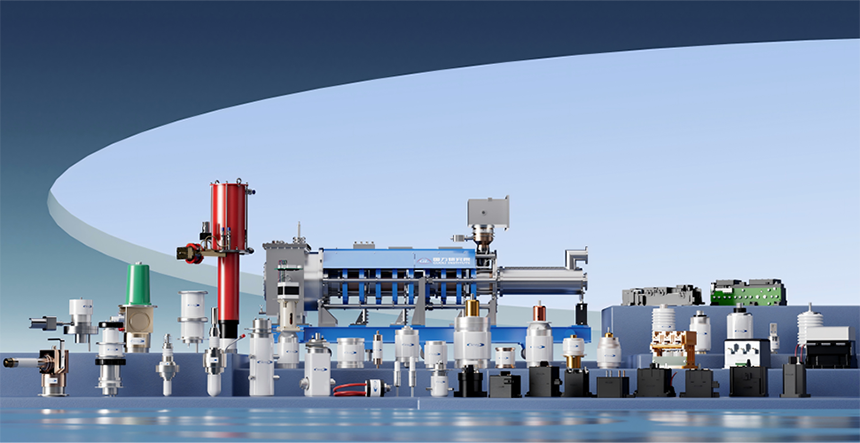

GLVAC ceramic vacuum capacitors have been widely used in modern high-end manufacturing equipment due to their unique performance advantages. In broadcast communication equipment, it serves as tuning, coupling, filtering, and other components to ensure the stability and accuracy of signal transmission. In semiconductor manufacturing equipment, it is used for plasma deposition and etching processes, which have a crucial impact on process accuracy and stability. In addition, in the fields of high-frequency industrial equipment, medical analysis and treatment equipment, GLVAC vacuum capacitors also play an irreplaceable role.

As electronic components of the new era, the use of vacuum capacitors should be standardized and regulated.

Suggestions for preventing failure:

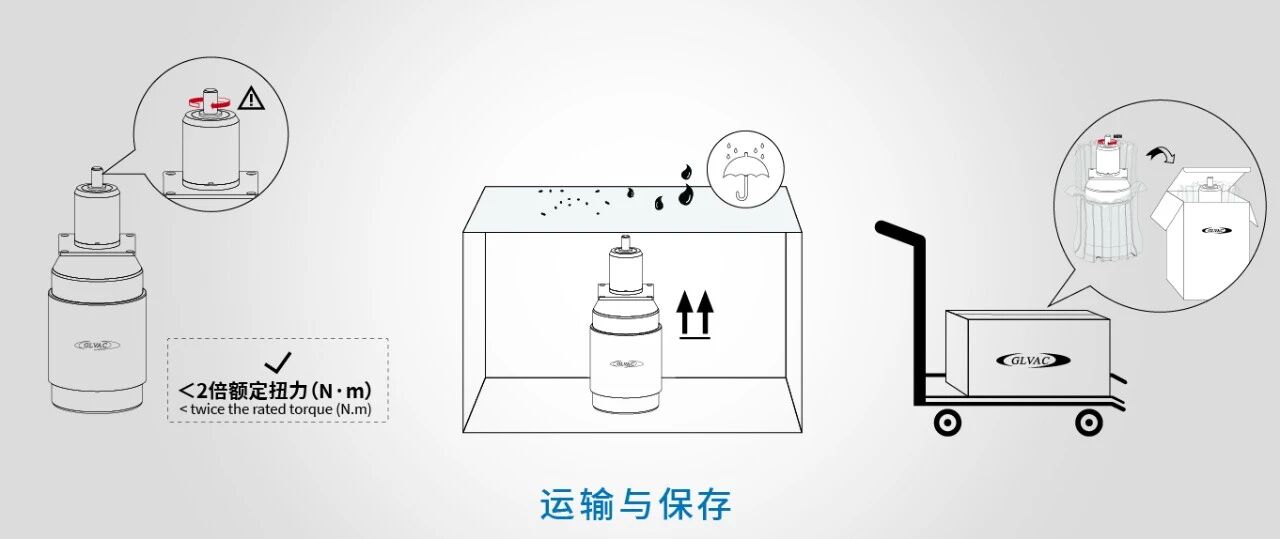

1) Strengthen the management of transportation, storage, and usage environment. The internal breakdown voltage of vacuum capacitors mainly depends on the surface state and gap size between the electrodes. As the electrodes are made of copper strips, the material is relatively soft and the gap between the electrodes is small. Therefore, accidental bumps and impacts may cause internal deformation, irreparable damage, and avoid dirty usage environments that may cause excessive leakage current and external creepage phenomena.

2) Enhance the cooling efficiency of the product during use. The normal operating current of capacitors is achieved under normal cooling conditions. Once the cooling efficiency decreases or is insufficient, it is easy to cause the product to overheat and shorten its lifespan.

3) Strengthen maintenance: Due to lack of lubrication, the lubricating grease of vacuum capacitors is prone to failure under high temperature operation, causing excessive wear and jamming of the threads of the rotating screw. Regular cleaning and lubrication of the rotating screw should be carried out to avoid product jamming.

4) Correct installation: Reduce mechanical stress. Do not forcefully install capacitors when there is an error in the position of the threads and connectors. The installation thread should be tightened evenly and slowly at the diagonal position to avoid excessive force that may cause deformation of the installation parts.

5) Correct operation. Due to the constant back and forth movement of the corrugated tube under certain stress, it is prone to metal fatigue and gas leakage. The greater the stress, the more repeated the movement, and the faster the fatigue speed, which can easily lead to sudden failure. Try to avoid unnecessary rotation of the vacuum capacitor, shorten the usage stroke, and extend the life of the bellows.

Ceramic vacuum capacitors, as precision components at the top of the electronic industry pyramid, have strict quality requirements for storage, use, and maintenance processes. Proper usage standards are essential for maximizing the performance of ceramic vacuum capacitors, which plays a significant role in improving equipment reliability and reducing maintenance costs.

分享

Latest News

-

Company News

2026/02/09

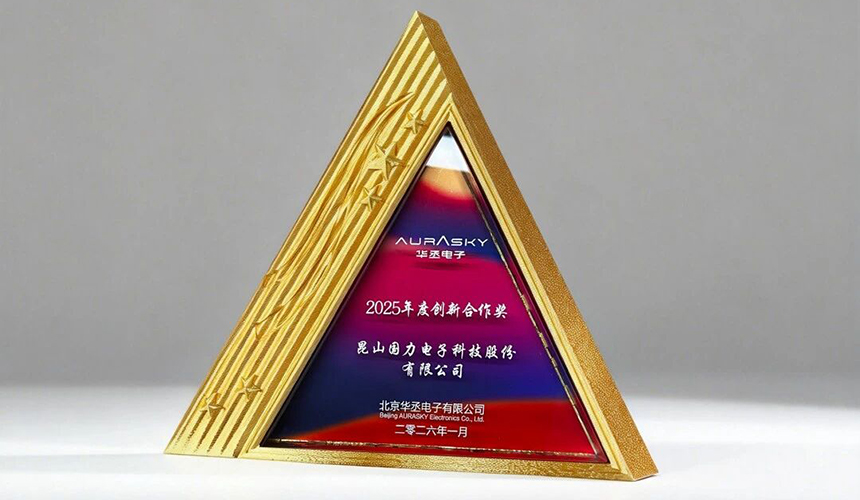

GLVAC Honored with NAURA's "2025 Annual Innovation Partnership Award"Recently, representatives from Beijing Huacheng Electronics Co., Ltd. — a subsidiary of NAURA — visited GLVAC Beijing office in person to present the company with the "2025 Annual Innovation Partnership Award."

More Details

-

Company News

2025/12/19

CW Magnetron: A Steady Source of Microwave Energy for Industry and Scientific ResearchIn the evolution of microwave technology, the magnetron has played a pivotal role. Among its various types, the continuous wave (CW) magnetron stands out as a crucial component due to its ability to deliver stable, continuous microwave energy over extended periods.

More Details

-

Company News

2025/12/17

Breaking Through Energy Boundaries: A Comprehensive Overview of High-Power Magnetron Applications Across IndustriesAs a core device capable of efficiently generating microwave energy, the magnetron has continuously shattered boundaries in energy applications since its inception.

More Details

-

Company News

2025/12/08

High-Power Magnetrons Empower Microwave Sources to Unlock New Diamond ApplicationsDiamond, the hardest material in nature, is rapidly expanding into high-end fields such as semiconductor thermal management, power electronics, quantum technologies, and optical devices.

More Details

-

Company News

2025/10/22

Vacuum Interrupter: the core component that ensures reliable operation of the power gridIn the power equipment system, the vacuum Interrupter, as the core component of the vacuum switch, plays an important role in connecting, carrying, and breaking current.

More Details

-

Company News

2025/10/14

Maintenance and use of GLVAC vacuum capacitorsGLVAC ceramic vacuum capacitors have been widely used in modern high-end manufacturing equipment due to their unique performance advantages.

More Details

-

Company News

2025/08/08

GLVAC endows eVTOL with new powerCurrently, the low-altitude economy is experiencing vigorous development, and low-altitude passenger transport is undoubtedly one of its most valuable applications.

More Details

-

Company News

2025/07/04

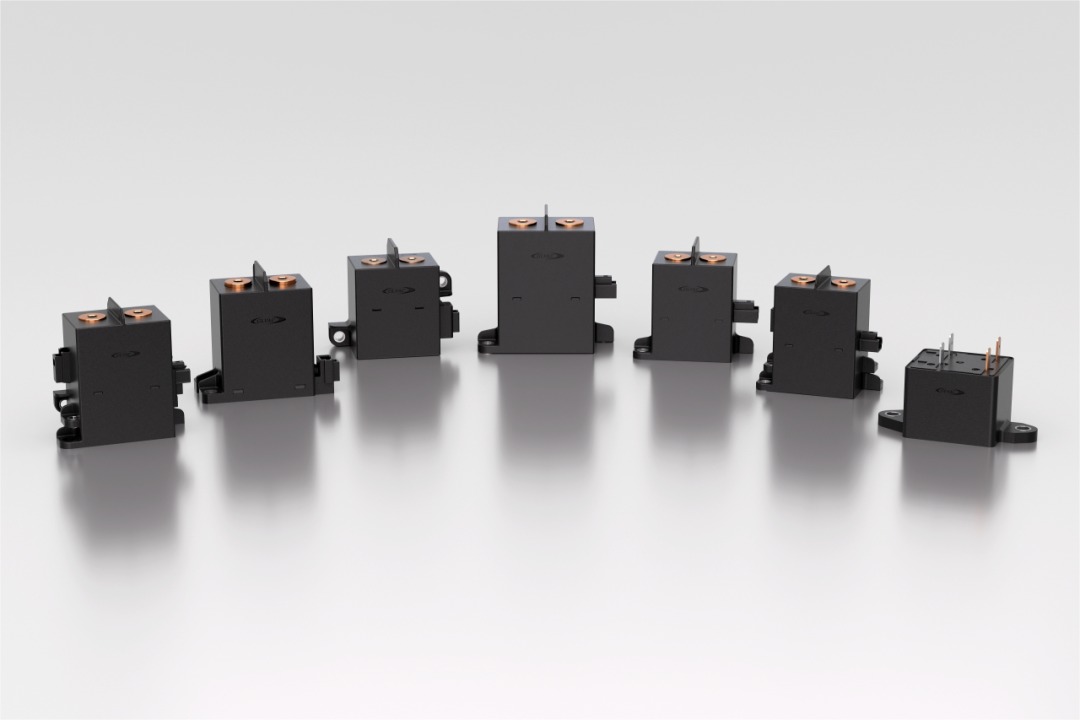

Unveiling the "High-Voltage Guardian" of New Energy Vehicles: How Critical Is This Little Component?As new energy vehicles accelerate toward a 1000V high-voltage platform, while driving efficiency is significantly enhanced

More Details

-

Company News

2025/06/12

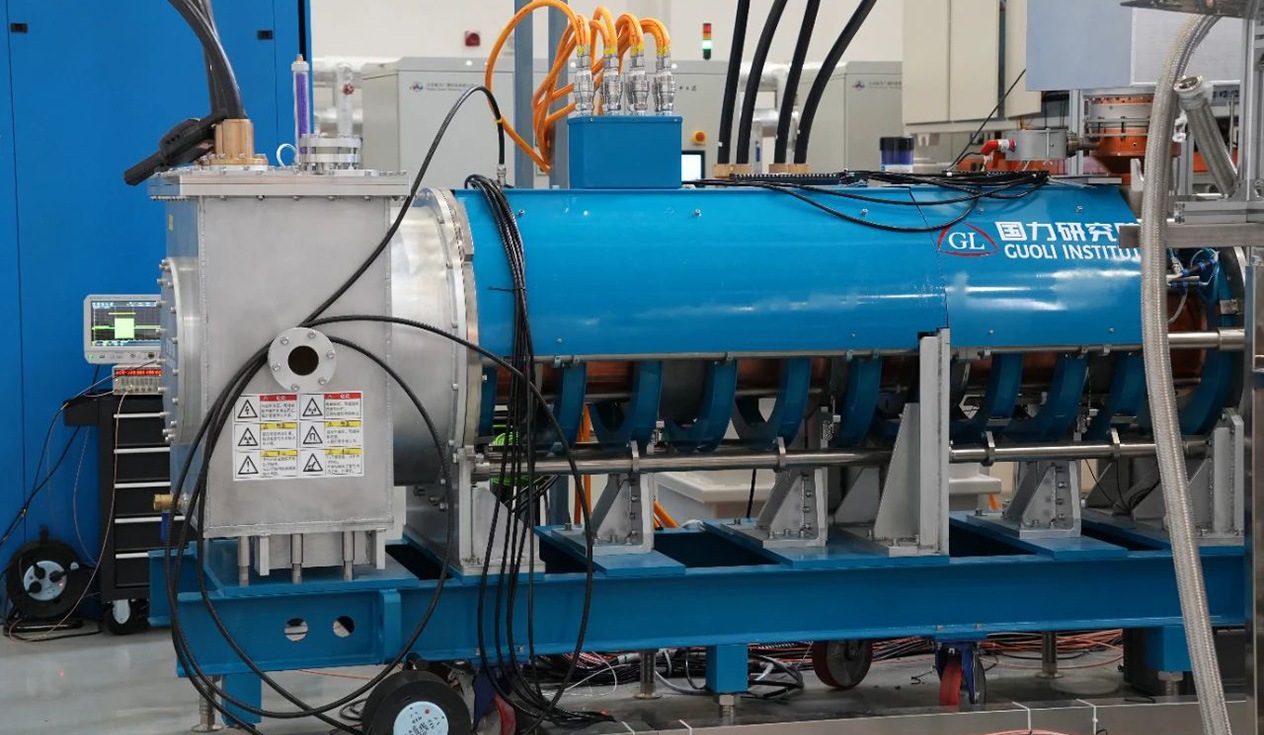

The world's first P-band high-power metamaterial klystron has been successfully developedOn June 7, 2025, led by the accelerator RF team of the China Spallation Neutron Source (CSNS), GLVAC in collaboration with the research group of Professor Zhaoyun Duan from the School of Electronic Science and Engineering at University of Electronic Science and Technology of China

More Details

-

Company News

2025/04/11

Ruipu Electric showcases its energy storage switch solution at the 13th ESIEOn April 10, 2025, the 13th Energy Storage International Conference And Expo(ESIE2025) grandly kicked off at the Capital International Exhibition Center of China. This exhibition has attracted top energy storage companies from home and abroad to participate, exploring the role of core technologies and system integration in promoting industrial upgr

More Details

-

Company News

2024/11/14

Electronica 2024On November 12th, the highly influential event in the global electronics industry, electronica 2024, grandly opened at the Munich Exhibition Center. GLVAC showcased its star exhibits such as semiconductors, new energy, energy storage, and scientific devices at this exhibition.

More Details

-

Company News

2024/11/07

Guoli Yuantong signed a cooperation agreement with Indian listed company Sterling ToolsOn November 6, 2024, Guoli Yuantong New Energy Technology Co., Ltd. (hereinafter referred to as "Guoli Yuantong") and Sterling Tools Ltd. (hereinafter referred to as "Sterling") held a signing ceremony in Kunshan, Jiangsu Province.

More Details

-

Company News

2023/12/12

Guoli Yuantong was awarded the 2023 Collaboration Contribution Award by SEVBOn December 9, 2023, Kunshan Guoli Yuantong New Energy Technology Co., Ltd. (referred to as "Guoli Yuantong")

More Details

-

Company News

2023/11/09

Guoli Yuantong Won the "Chinese Heart" 2023 Annual Powertrain Components Gold AwardOn October 27, the 2023 "Chinese Heart" Annual Powertrain Components Evaluation, co-organized by Auto Sports magazine and the School of Automotive Engineering at Shanghai Jiao Tong University, with support from the Government of Gaoyou City, Jiangsu Province, came to a successful conclusion.

More Details

-

Company News

2021/12/31

GLVAC is honored to receive the CATL 2021 Annual Outstanding Supplier AwardAt the moment when the New Year's bells are about to ring, on the last day of 2021, Guoli Yuantong received the most precious New Year’s gift

More Details

-

Company News

2020/03/10

The first prototype of the CEPC 650 MHz klystron successfully completed tests achieving a pulse power of 800 kW and a continuous wave (CW) power of 400 kWOn February 27 and March 7, the first prototype of the 650 MHz klystron for the Circular Electron and Positron Collider (CEPC)

More Details

-

Company News

2018/07/13

NAURA visits GLVACOn July 12, 2018, Mr. Jinrong Zhao, President and CEO of NAURA Technology Group Co., Ltd., came to visit our company, Mr. Jianping Yin, President of Kunshan GuoLi Electronic Technology Co., Ltd., received and accompanied NAURA team, and both parties had a business negotiation.

More Details

Get Professional Solutions

We are looking forward to engaging with you to explore more solutions for electric vacuum devices.