2025/07/04

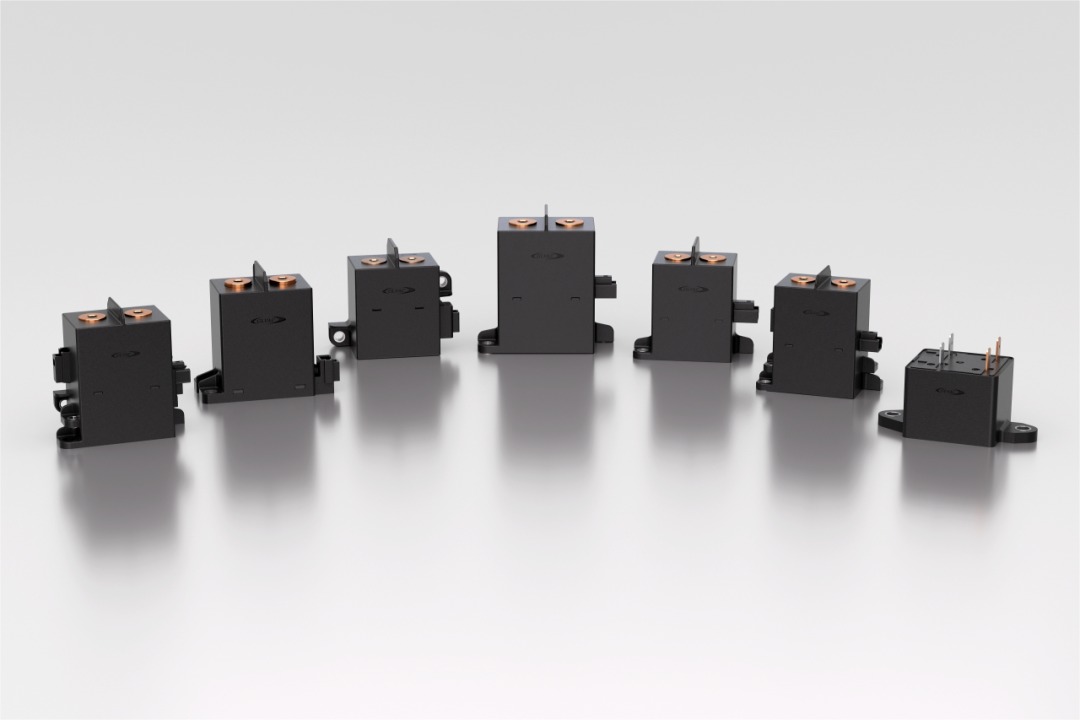

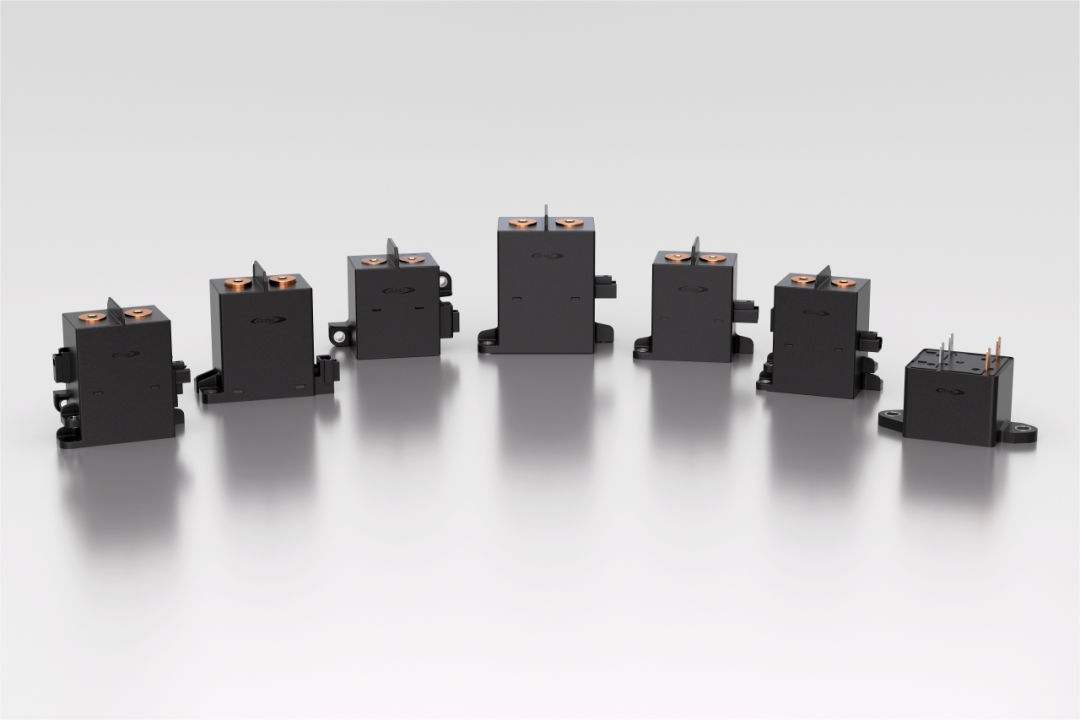

As new energy vehicles accelerate toward a 1000V high-voltage platform, while driving efficiency is significantly enhanced, the requirements for the vehicle's "safety guardian" also become more stringent. Today, let's get to know a key player that silently protects the safety of high-voltage circuits — the HV relay, also known as a DC contactor. Though small and unassuming, it acts as the "pacemaker" ensuring the vehicle's safe and stable operation. Facing the challenges of high-voltage platforms, GLYT (Guoli Yuan Tong) continues to invest in R&D, dedicated to providing DC contactor solutions that meet the demands of higher voltage and larger current applications.

High-Voltage Relay: The "Dedicated Switch" for the High-Voltage Era

Imagine the relays in traditional fuel vehicles — they control windshield wipers, windows, and operate at low voltages like 12V or 24V. However, in new energy vehicles, the heart of the system — the high-voltage architecture — runs at dramatically higher levels: typically 400V, 800V, and now rapidly advancing toward 1000V! Under such extreme voltage conditions, standard low-voltage relays are simply not up to the task.

This is where high-voltage relays come into play! Simply put, they are "electronic switches" capable of precisely controlling the on/off states of circuits under high voltage and large current conditions.

Why are they so special?

More Complex Structure: Designed with special insulating materials and structures to withstand high voltages. GLYT's DC contactors feature optimized insulation design and premium materials, ensuring long-term reliable insulation even on platforms exceeding 1000V.

Precious Contact Materials: Equipped with noble metal alloys such as silver and copper alloys that offer excellent conductivity and wear resistance.

Built-in "Firefighter": Arc suppression is a core technology! When a high-voltage circuit is interrupted, powerful electric arcs can form. The arc suppression system quickly extinguishes these arcs, preventing damage to contacts and potential safety incidents — a critical feature absent in low-voltage relays. GLYT has deep expertise in arc suppression technologies; its advanced arc chamber design efficiently and reliably interrupts high-energy arcs, playing a key role in ensuring overall system safety.

Dissecting the "Black Box": How a High-Voltage Relay Works

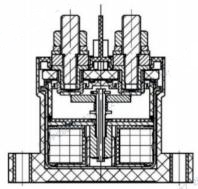

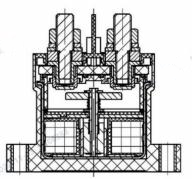

Don't be fooled by its compact size — inside lies a highly precise "automated kingdom":

Coil (The Commander): When energized, it generates a magnetic field and serves as the power source for the relay's operation.

Armature (The Executor): It is attracted or released by the magnetic field, driving the movement of the contacts.

Contacts (The Gatekeepers): The moving contact connects with or separates from the stationary contact, either closing or opening the circuit. Contacts are categorized into normally open (NO) and normally closed (NC) types.

Arc Chamber (The Firefighter): Quickly and safely extinguishes the high-energy arc generated when contacts separate.

Housing (The Armor): Protects the delicate internal components.

Working Mechanism:

Energized State: Coil generates a magnetic field → Armature is pulled in → Moving contact closes (NO contact connects the circuit).

De-Energized State: Magnetic field disappears → Spring returns the armature to its original position → Moving contact separates (circuit is interrupted).

The entire process is fast and precise, achieving efficient control through electromagnetic induction.

Energized State

De-energized State

Key Performance: "Health Indicators" That Determine Protection Capability

Choosing the right high-voltage relay is critical. The following parameters serve as its "health indicators":

Rated Operating Voltage/Current: Must precisely match the vehicle's high-voltage system (e.g., 400V/800V/1000V platforms) and maximum operating current. Otherwise, it may result in underperformance ("a small horse pulling a big cart") or unnecessary cost overkill. GLYT's product line covers mainstream and forward-looking platforms from 400V to 1000V and beyond.

Overload Current Capacity: During acceleration or uphill driving, current surges dramatically. The relay must be able to withstand these sudden high-current impacts (e.g., rated at 250A but capable of handling 500A for short periods), ensuring stable power delivery.

Electrical Life: Refers to the number of times the relay can reliably switch on and off. Frequent switching wears down the contacts; longer life means lower maintenance costs and higher reliability. This depends heavily on contact material and arc suppression performance.

Maximum Breaking Current: A safety red line! During a short circuit, current spikes sharply — this parameter determines whether the DC contactor can safely interrupt the fault current (e.g., up to 10,000A). It is crucial for preventing catastrophic failures. This is one of GLYT's core performance highlights, with contactors designed to handle extreme short-circuit scenarios with robust breaking capability.

Coil Parameters: Rated voltage (commonly 12V or 24V), pick-up/release voltage, power consumption, and resistance must all be compatible with the vehicle's control power supply.

Contact Parameters: Key focus areas include overload capacity, service life, and breaking current.

Ubiquitous Protection: The Core Battlegrounds of High-Voltage Relays

The high-voltage relay (DC contactor) serves as the "safety cornerstone" of the high-voltage system in new energy vehicles, playing a critical role across multiple key systems:

1. "Trusted steward" in Battery Management System (BMS):

Main Relay: Acts as the "main switch" for battery output, controlling the on/off state of the vehicle's entire high-voltage power supply.

Pre-Charge Relay: A "buffer guardian" that enables pre-charging before the main relay closes, preventing high-voltage surges from damaging sensitive components.

Charge/Discharge Isolation: Precisely controls the charging and discharging circuits, quickly disconnecting the battery in case of faults to ensure safety.

2. "Safety Guardian" in the Charging System:

Establishing Safe Connection: Performs multiple safety checks before charging begins, only enabling the circuit after confirming all conditions are safe.

Smart Current Control: Dynamically adjusts the charging current (fast charge / trickle charge) based on battery status and charging station power, protecting the battery and improving efficiency.

Fault Response vanguard: Continuously monitors the system; upon detecting overvoltage, overcurrent or other anomalies, it immediately cuts off the circuit and issues an alert — safeguarding both the vehicle and charging station. (Example: A driver encountered a charging station malfunction during charging — the high-voltage relay responded promptly, cutting off power and preventing significant damage.)

3. "Comfort Enabler" in Auxiliary Systems:

Air Conditioning Compressor Control: Controls the compressor's on/off cycles, enabling precise temperature control and energy savings. Without it? Summer feels like a steamer, winter like a freezer!

Seat Heating/Ventilation Control: Manages circuit switching to deliver a comfortable climate-controlled seating experience — keeping you warm in winter and cool in summer.

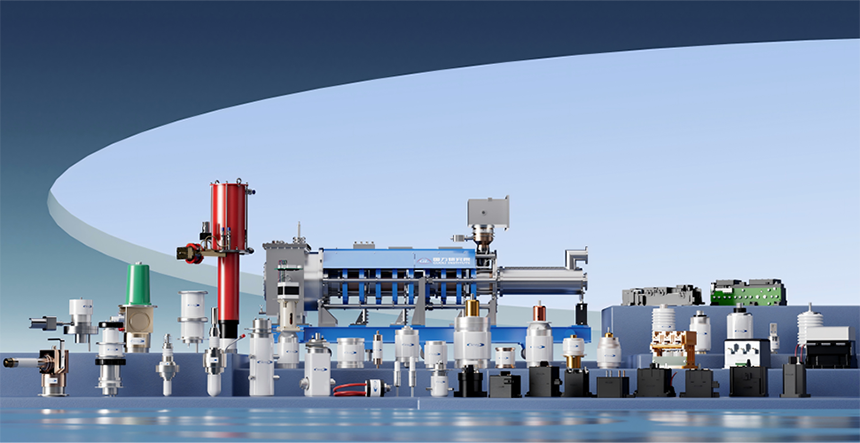

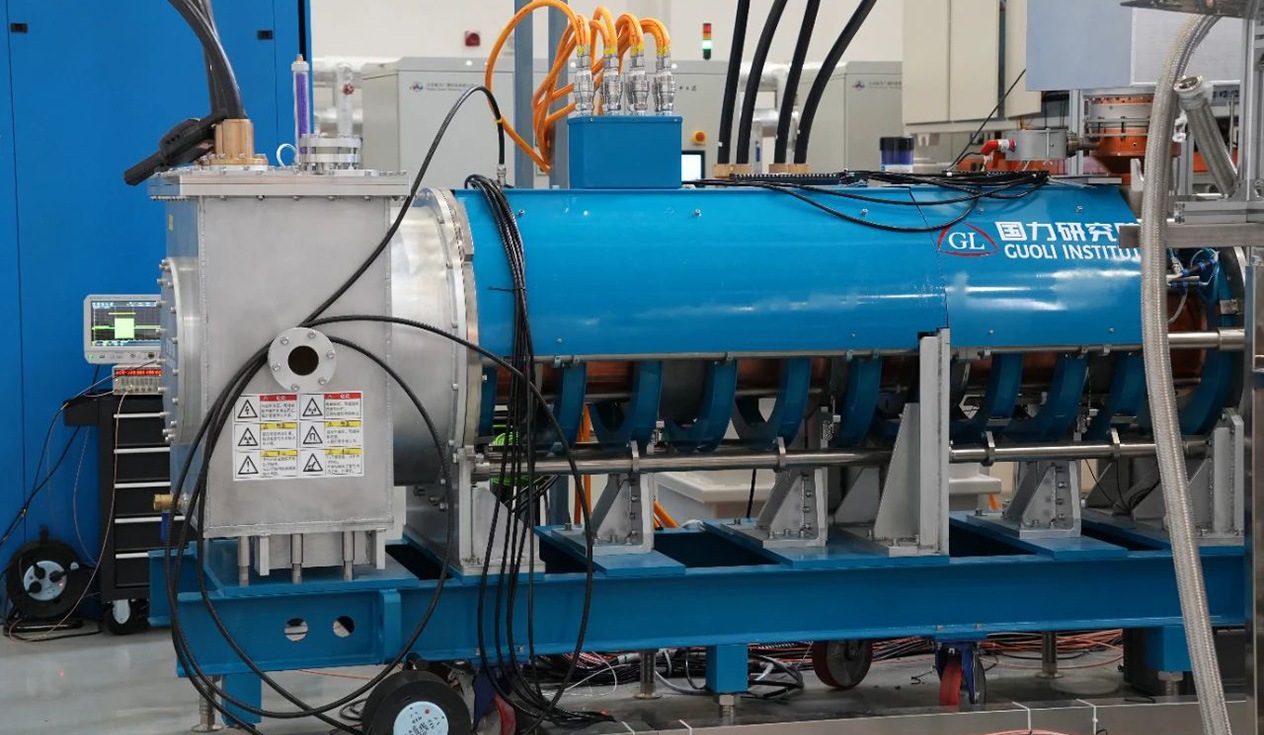

As one of the key domestic suppliers of DC contactors, GLYT (Guoli Yuan Tong) has earned widespread recognition for its high reliability, strong breaking capacity, and excellent adaptability to high-voltage platforms. Its products are now widely applied in the battery systems, charging systems, and auxiliary systems of numerous leading new energy vehicle brands, providing essential hardware support for safe and efficient vehicle operation.

From 400V to 800V, and now advancing toward 1000V, every voltage leap in new energy vehicles is made possible with the strong support of the DC contactor — the silent "guardian of high voltage." It precisely controls the flow of energy, ensuring the safety and stability of every start-up, drive, and charging cycle. Understanding it, selecting the right one, and maintaining it properly means building a solid line of defense for the safe and efficient performance of new energy vehicles.

Next time you enjoy the convenience and quiet comfort of electric mobility, don't forget to pay tribute to this unsung hero behind the scenes!

Latest News

Get Professional Solutions

We are looking forward to engaging with you to explore more solutions for electric vacuum devices.